|

| Handling of Rotating Resistant Ropes When being reeled on to a machine, a rotation resistant rope must be handled with care. Unless by prior agreement, rotation resistant ropes will always be supplied in reels if any reason they have to be removed from a machine. The most common problem encountered in rotation resistant rope is "birdcaging" which is caused by: 1) Kinking during lifting 2) Turn being taken out of outer cover strands (living the lay looser) allowing the inner layers to "pop". 3) Incorrect hand splicing, rotation resistant ripes should only be spliced by an experienced and competent splicer trained to splice this type of wire rope. 4)Tight or badly maintained sheaves. 5)Inadequate or incorrect "running-in"before mormal duty. Safety Factor of Wire Rope 鋼絲繩的安全系數 It is difficult to fix the safety factor for each type of wire rope to be used for various equipments, as this factor depends not only on the load carried, but also on the speed of the rope working, the kinds of lifting used for rope ends, the acceleration and deceleration and deceleration, length of wire rope, the number, size and arrangement of sheave and drum etc...... The following safety factors are minimum requirements for safety and economy in the common installation. The safety factor also depends upon the factors causing abrasion and corrosion, the facilities for inspection, and the danger to life and property.

|

||||||||||||

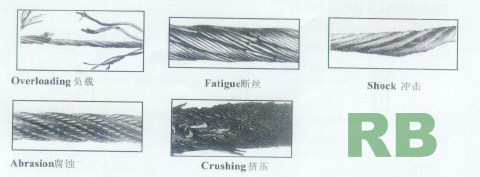

Causes of Premature Wire Rope Failure All the factors sonsidered on the previous page may affect the life of a working rope, and their relative importance can be crucial to choose the proper rope for a particular application. In the following discussion, it shold be remenbered that often two or more of these factors apply to any indivedual case: |

||||||||||||

Copyright c Rainbowindco.com. All Rights Reserved. |